1. He aha ka adaimana circular saw maka

ʻO ka pahi ʻike pōʻai daimanahe mea hana maʻa mau, ʻo ia ka ʻili ʻili me kahi ʻoki daimana ma ka ʻaoʻao o loko a i waho paha o ka ʻili.Hoʻohana nui ʻia ia i ka hana ʻana i nā mea paʻakikī a palupalu e like me nā pōhaku a me nā seramika.ʻElua mau ʻāpana o ka ʻili daimana: ka substrate a me ka lau.ʻO ka substrate ka ʻāpana kākoʻo nui o ka lau adhesive, ʻoiai ʻo ka ʻili ka ʻāpana ʻoki e hoʻomaka i ka wā e hoʻohana ai.E hoʻopau mau ka lau i ka wā e hoʻohana ai, ʻaʻole e pau ka substrate.Hoʻopili ʻia nā ʻāpana daimana i ka metala i loko o ke poʻo ʻoki, kahi mea e ʻoki ai i ka ʻoki ʻoki ʻana o ka mea i hana ʻia i ka wā o ke kaʻina hana.I ka wā e hoʻohana ai, hoʻopau pū ʻia ka matrix metala a me ke daimana.ʻOi aku ka maikaʻi no ka ʻai ʻana o ka matrix metala ma mua o ke daimana, kahi e hōʻoia ai i ka ʻoi o ke poʻo ʻoki a me ke ola lawelawe o ke poʻo ʻoki.

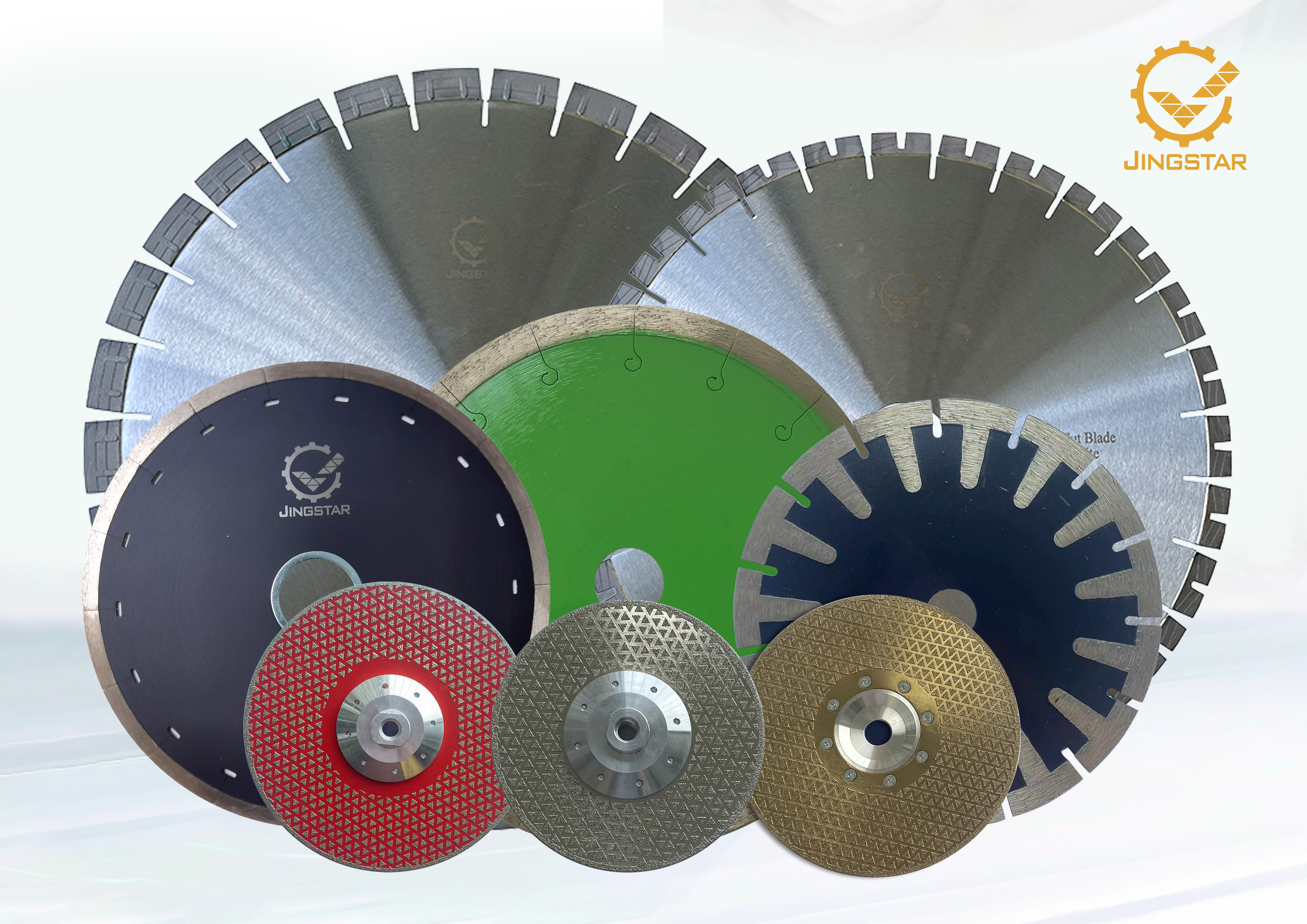

ʻO ke anawaena o kadaimana circular saw bladeshe nui, me nā lau kālai ʻia he mau millimeters a me nā ʻili maka nui he mau mika ke anawaena.Nui nō hoʻi nā mea ʻoki, a ʻokoʻa ke ʻano, ka paʻakikī, a me ka nui o nā mea ʻoki.No laila, ʻokoʻa nā ʻano hana o kā lākou hana ʻana a me ka hana ʻana, nā mea maka i hoʻohana ʻia, a me nā koi hoʻohana.

2、 Hoʻokaʻawale odaimana circular saw blades

ʻO ka pahi ʻike pōʻai daimanaʻO ia ka mea hana ʻili maʻamau i kēia manawa ma ka ʻoihana pōhaku o Kina, ʻo ia ka mea maʻamau i ke ʻano he poepoe.Hoʻohana ia i nā ʻano e like me ka pauka metallurgy a i ʻole electroplating e hoʻokomo i nā ʻāpana daimana a puni ka substrate.Ke hoʻohana nei i ka ikaika kiʻekiʻe a me ka paʻakikī o nā ʻāpana daimana e ʻako a wāwahi i nā mea ʻē aʻe no ka ʻoki ʻana.Nui nā ʻano odaimana circular saw bladesa paʻakikī hoʻi kā lākou hoʻokaʻawale ʻana.Nui nā ʻano hoʻohālikelike:

1. Hoʻokaʻawale ʻia ma ke kaʻina hana:

(1) ʻO ka pahi ʻike daimana sintered

ʻElua ʻano o ka sintering: cold press sintering a me hot press sintering.

(2) Ka wili daimana ʻike maka

ʻElua ʻano o ka brazing a me Laser beam welding.ʻO Brazing ka hoʻopaʻa ʻana i ke poʻo ʻokiʻoki a me ka substrate ma o ke ʻano hoʻoheheʻe wela kiʻekiʻe, e like me ke kiʻekiʻe-frequency induction brazing saw blade, vacuum brazing saw blade, etc.Hoʻohana ʻo Laser welding i ke kukui laser wela e hoʻoheheʻe i ke poʻo ʻoki a me ka lihi pili o ka substrate e hana i ka hoʻopaʻa metala.

(3) Electroplated daimana ʻike maka

ʻO ia ke kaʻina hana o ka hoʻopili ʻana i ka pauka maka i ka substrate ma o ka electroplating.Eia nō naʻe, ma muli o ka pollution koʻikoʻi, ke hoʻopau mālie nei ka ʻāina i kēia ʻano hana electroplating.

2. Hoʻokaʻawale ʻia e ka mea hana:

ʻO ka pahi ʻoki ʻoki marble, ka ʻili ʻoki granite, ka ʻili ʻoki ʻokiʻoki, a pēlā aku.

3. Hoʻokaʻawale ʻia ma ke ʻano:

ʻO nā lau ʻike maka mau, nā ʻili ʻili ʻano maka, nā ʻili ʻano turbine, a pēlā aku.daimana circular saw blades, a he nui nō hoʻi nā kumu kūikawādaimana circular saw blades.E koho i nā ʻano like ʻole o nā ʻili daimana no ka hana ʻana i nā mea like ʻole.

3、 Nā hiʻohiʻona nui odaimana circular saw makaʻoki ʻoki

Loaʻa ka maikaʻi o ka ʻoki ʻana i ka maka o ka pōʻaiapuni o ka hana maʻalahi, ka hana kiʻekiʻe, a me ka maikaʻi o ka hana ʻana.Akā, nui ka walaʻau a maikaʻi ʻole ka paʻa o ka pahi.I ka wā o ka ʻoki ʻana, ʻoi aku ka maikaʻi o ka ʻike maka i ka haʻalulu a me ka ʻae ʻana, e hopena i ka ʻoki ʻia ʻana o ka mea hana.

4、 Nā mea e pili ana i ka pono a me ke ola odaimana circular saw blades

Nā mea e pili ana i ka pono a me ke ola odaimana circular saw bladese hoʻokomo i nā ʻāpana kaʻina hana ʻoki, ka pae daimana, ka nui o nā ʻāpana, ka hoʻopaʻa ʻana, a me ka paʻakikī paʻa.

1. Nā palena ʻili

(1) ʻIke i ka māmā ʻoki

Ma ka hana hana, ka laina laina odaimana circular saw bladesua kaupalena ʻia e nā kūlana o nā mea hana, ka maikaʻi o ka ʻike maka, a me nā waiwai o ka pōhaku i ʻeli ʻia.Ma keʻano o ke ola lawelawe a me kaʻokiʻana i ka maikaʻi o ka'ōpala saw, pono e kohoʻia ka laina laina o ka'ōpala ma muli o nā waiwai o nā pōhaku likeʻole.

(2) Ka hohonu ʻeli

I loko o ka ʻae ʻia o ka hana mīkini ʻike a me ka ikaika mea paahana, pono e koho ʻia nā hohonu ʻoki nui e like me ka hiki ke hoʻomaikaʻi i ka ʻoki ʻoki.Ke loaʻa nā koi no ka ʻili mīkini, pono e hoʻohana i ka ʻoki liʻiliʻi hohonu.

(3) Ka māmā hānai

ʻO ka wikiwiki hānai ka wikiwiki hānai o ka pōhaku i ʻeli ʻia.Pono e koho ʻia kona waiwai ma muli o nā waiwai o ka pōhaku ʻili.ʻO ka ʻōlelo maʻamau, ʻo ka ʻeli ʻana i nā pōhaku palupalu, e like me ke kinikini, hiki ke hoʻonui i ka hohonu o ka ʻili ʻana a hoʻemi i ka wikiwiki o ka hānai, ʻoi aku ka maikaʻi o ka hoʻomaikaʻi ʻana i ka nui o ka sawing.Hiki ke hoʻonui i ka wikiwiki o ka hānai ʻana i ka ʻeli ʻana i ka granite maikaʻi a me ka homogeneous.Inā haʻahaʻa loa ka wikiwiki o ka hānai ʻana, ua maʻalahi ka lepo i ka ʻili daimana.Eia nō naʻe, i ka ʻike ʻana i ka granite me ke ʻano o ka palaoa a me ka paʻakikī ʻole, pono e hoʻemi ʻia ka wikiwiki o ka ʻoki ʻana, inā ʻaʻole ia e hoʻoneʻe i ka maka ʻili a hoʻoheheʻe i ke daimana, a laila e hōʻemi i ka ʻoki ʻoki.

2. Ka nui o ke daimana

ʻO ka nui o nā ʻāpana daimana maʻamau mai 30/35 a 60/80 mesh.ʻO ka ʻoi aku ka paʻakikī o ka pōhaku, ʻoi aku ka maikaʻi o ka nui o nā ʻāpana e koho ʻia.No ka mea, ma lalo o nā kūlana paʻi like, ʻoi aku ka maikaʻi o ke daimana, ʻoi aku ka ʻoi aku o ka ʻoi, kahi mea e pono ai no ka ʻoki ʻana i nā pōhaku paʻakikī.Eia kekahi, ʻo ka maʻamau ʻo ka nui o nā lau ʻike ʻike e pono ai ke ʻoki ʻoki kiʻekiʻe, a pono e koho ʻia nā nui o nā ʻāpana coarser e like me 30/40 mesh a me 40/50 mesh;He haʻahaʻa ka maikaʻi o ka ʻoki ʻoki ʻana o nā lau ʻili liʻiliʻi a pono i nā ʻāpana ʻoki pōhaku maʻemaʻe.He mea pono ke koho i ka nui o na mea liilii, e like me 50/60 mesh a me 60/80 mesh.

3. ʻO ka manaʻo daimana

ʻO ka manaʻo daimana e pili ana i ka nui o ka puʻunaue daimana i loko o ka matrix papa hana.Wahi a nā lula, ʻo 100% ka manaʻo o 4.4 carats o daimana i kēlā me kēia cubic centimeter o ka papa hana matrix, a ʻo ka ʻike ʻana o 3.3 carats o ke daimana he 75%.Hōʻike ka manaʻo o ka leo i ka nui o ke daimana i loko o ka poloka a ʻōlelo ʻia he 100% ka nui o ke daimana i ka 1/4 o ka nui o ka nui.ʻO ka hoʻonui ʻana i ka manaʻo o ke daimana ke manaʻo ʻia e hoʻolōʻihi i ke ola o ka maka ʻili, no ka mea, ʻo ka hoʻonui ʻana i ka ʻike e hōʻemi ana i ka ʻoki ʻoki ʻana i kēlā me kēia daimana.Akā,ʻo ka hoʻonuiʻana i ka hoʻonuiʻana e hoʻonui i ke kumukūʻai o ka maka maka, no laila, aia kaʻoi aku o ka hoʻokele waiwai e hoʻonui me ka hoʻonuiʻana i ka pono o kaʻeli.

4. Ka paakiki o ke poo oki mea paa:

ʻO ka ʻōlelo maʻamau, ʻoi aku ka kiʻekiʻe o ka paʻakikī o ka paʻa, ʻoi aku ka ikaika o kona pale ʻana.No laila, i ka ʻeli ʻana i nā pōhaku me ka abrasive kiʻekiʻe, hiki ke kiʻekiʻe ka paʻakikī o ka mea paʻa;I ka ʻeli ʻana i nā pōhaku palupalu, pono e haʻahaʻa ka paʻakikī o ka mea hoʻopili;I ka ʻeli ʻana i nā pōhaku me ka abrasive kiʻekiʻe a me ka paʻakikī, pono ka paʻakikī o ka mea hoʻopili.

5、 Ke au hoʻomohala oʻO nā ʻili ʻili daimana

ʻO nā pahi ʻike pōʻai daimanaʻo ia nā mea hana nui i ka ʻoihana hana pōhaku.I nā makahiki i hala iho nei, ua piʻi nui ka nui o nā daimana hana i hoʻohana ʻia i ka ʻoihana hana pōhaku, a me ka noidaimana circular saw bladeske mahuahua nei no hoi.ʻO ka holoʻokoʻa, ka hoʻomohala ʻana odaimana circular saw bladesma ka aina a ma ka honua hoi keia mau hiohiona: ka hana ana i na maka pahi ike maikai a maikai loa, a me ka hooulu ana i na daimana kuikea o ka maka maka;E noʻonoʻo nui i ka noiʻi ʻana o ka pauka, matrix, a me ke kaʻina sintering;E noʻonoʻo nui i ka noiʻi e pili ana i ka sawability a me ka ʻeli ʻana o nā mea pōhaku;Ua hoʻomohala ʻia ka pahi wiliwili laser;E hoʻomohala i ka nuidaimana circular saw blades.I kēia manawa, ʻo ka noi ʻana odaimana circular saw bladeske laha nui nei.I ka wā e hiki mai ana, ke kuhikuhi hoʻomohala odaimana circular saw bladesʻo ia ka hoʻomaikaʻi ʻana i ka hana ʻoki ʻana, ʻike i ke ola o ka lau, hoʻemi i nā kumukūʻai hana, a loaʻa pū kekahi i ka mālama ʻana i ke kaiapuni.

Nānā: "Nīnau Nīnau a me nā mea hana daimana i ka ʻike" na Zhang Shaohe lāua ʻo Hu Yule

Ka manawa hoʻouna: ʻAukake-04-2023